brandnew spray gun ST-3225 – a real product highlight for the food industry

By developing this new product, our engineering department has successfully combined the best from two fields. The newly developed spray gun ST-3225 perfectly combines the ergonomic and fluidic advantages of a ball valve with the user safety and potential for saving water of a dry-shut spray gun.

Professional medium pressure spray gun applications often take several hours without any breaks. According to the directives for liquid jet sprayers by the association of commercial and industrial workers’ compensation insurance carriers a “dead man`s control” is imperatively prescribed. This means that the trigger of the spray gun has to be pulled during the complete operation time. It is strictly forbidden to block the trigger or to tie the trigger to the handle of the spray gun. Users often suffer from a tennis arm or carpal tunnel syndrome after pulling a gun over hours. That`s why they tend to work with ball valves that do not close automatically thus leading to dramatic injuries. By offering the new ST-3225 we have developed a spray gun that significantly reduces the risk of injuries as above-mentioned.

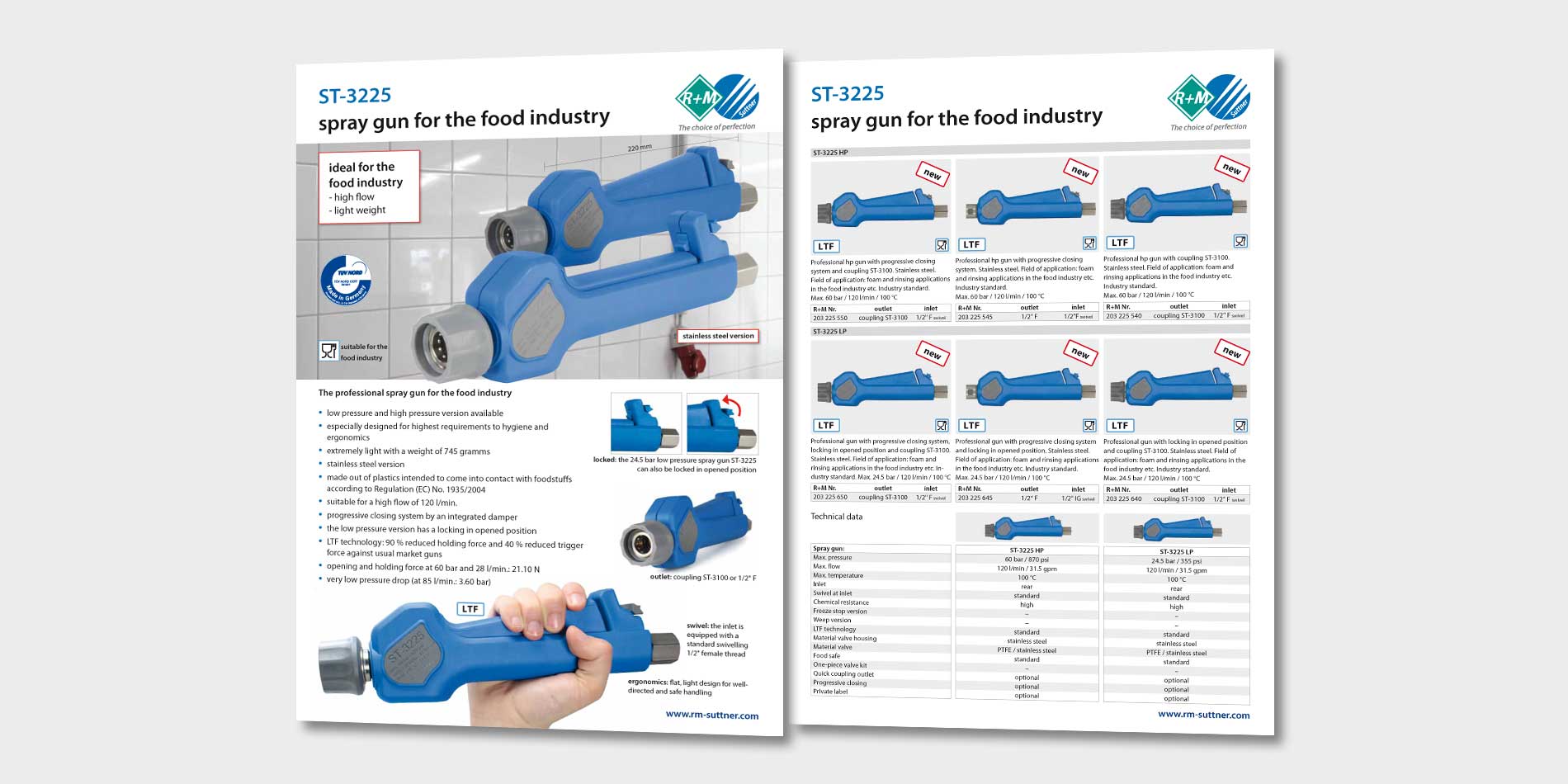

The ST-3225 is characterized by its linear valve design making an ergonomic handling possible:

- due to the natural position of the hand at the valve

- by very low opening and holding forces

- by a very small angle of activation of the trigger between on and off

- the linear design makes the machine cleaning in the food industry significantly easier as all 6 degrees of freedom of the human arm can be completely used

- the user is relieved from the hose weight by means of an ergonomic hose guide from the spray gun towards the user`s body. The weight of the hose is passed under friction to the upper part of the body. The hose weight is also reduced by the recoil of the exiting water jet.

Moreover, the ST-3225 guarantees the least possible pressure drop thus leading to more efficiency of the entire system. A better foam quality increases the exposure time at lower compressed air and less use of chemicals. An integrated quick coupling outlet offers great variability i.e. the possibility to foam, rinse or disinfect and if necessary with different lance lengths even for spots that are not easy to reach. The swivel integrated in the inlet of the hose effectively prevents a twisting of the hose even under pressure. A damped closing system prevents pressure shocks within pipelines.

It goes without saying that the ST-3225 is made out of plastics intended to come into contact with foodstuffs according to Regulation (EC) No. 1935/2004. All metal parts are made out of stainless steel. The spray gun`s weight is significantly reduced in comparison with customary spray guns. All plastic parts are break-proof and impact resistant as exclusively high quality materials are used for the material-optimized construction.

All further information about our ergonomic spray gun ST-3225 for the food industry are given on our data sheet.

ST-3225 – a great innovation in this field since years convincing by ergonomic, extremely robust and hygienic design.