What is the difference between Freeze stop and Weep?

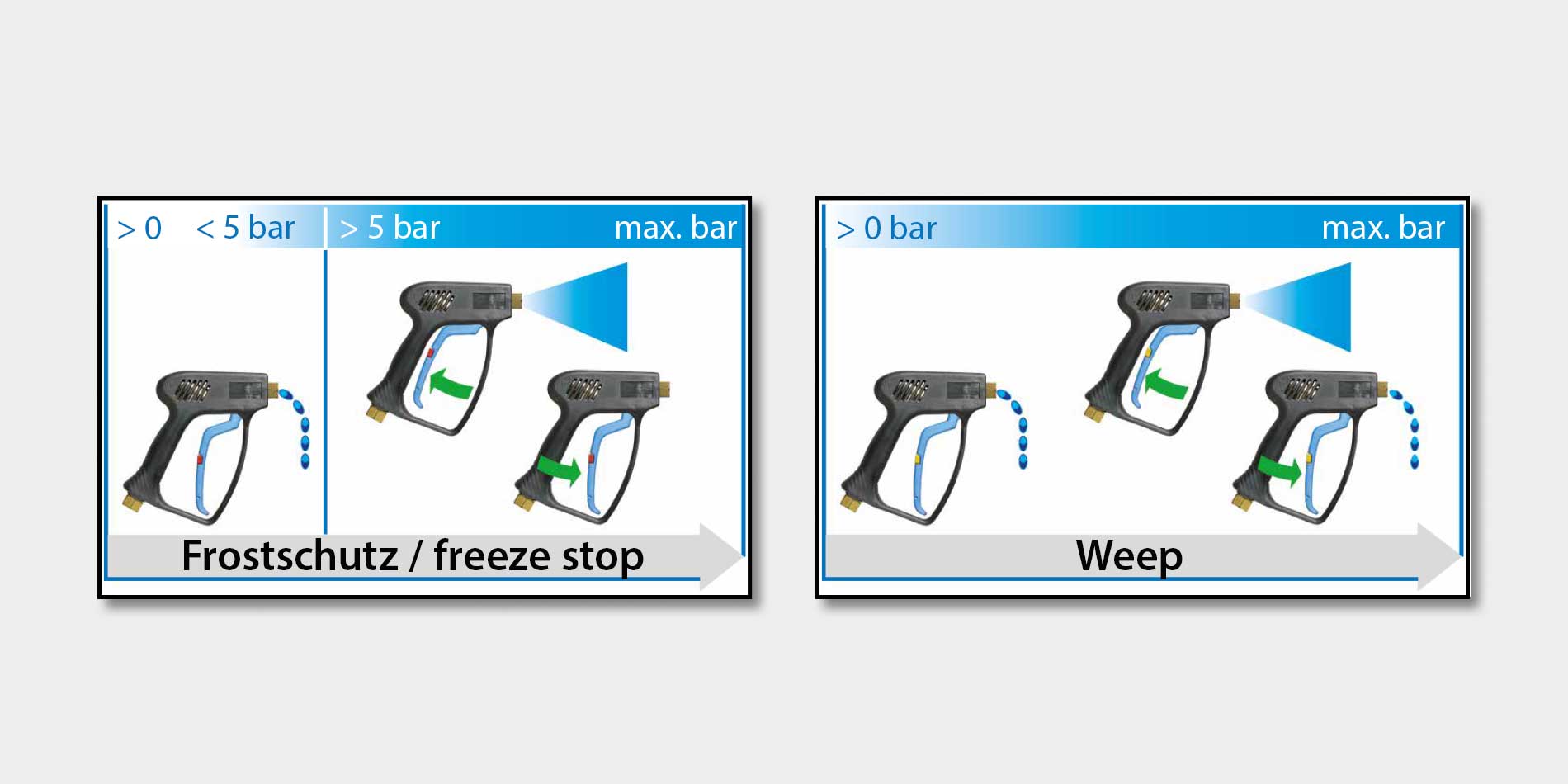

The figure clearly illustrates the different modes of action of the two freeze protection systems of high-pressure spray devices. Both designs are based on the physical effect of liquids tending less to freeze if they are in motion. This is why high-pressure guns in weep or frost stop design allow a certain quantity of water to pass the valve under the given conditions (in case of varying pressures) even if the lever is not actuated in order to keep the water in the piping, hose, and spray device in motion.

In case of guns in weep design this is implemented simply by a groove or notch in the seal seat of the valve which allows a reduced quantity of water to pass even if the lever is not actuated. This is effected in high-pressure mode if the high-pressure pump is activated as well as in low-pressure mode with water pipe pressure.

The so-called frost stop guns use a “valve-in-valve” technology, i.e. the actuating valve operated by means of the gun lever includes the actual automatic frost stop valve. By means of the actuating valve, the gun is opened and closed for cleaning purposes as usual. The integrated frost stop valve is actuated only in low-pressure mode (water pipe pressure). It is spring-operated and opens if the applied pressure falls short of about 5 bar. If this pressure increases, e.g. by activating the high-pressure pump, the frost stop valve closes automatically. Washing comfort is thus increased since no water escapes when the lance is removed from the holder.

R+M de Wit GmbH

R+M de Wit GmbH