Medium-pressure cleaning systems are indispensable in food production. However, vibrations transmitted through the spray gun to the operator’s hand and arm can pose potential health risks. Our scientific approach systematically examines these exposures according to ISO 5349-1, demonstrating how ergonomic design and technical optimization can significantly reduce vibration levels.

The internationally recognized ISO 5349-1:2001 standard was applied to assess vibration exposure. It defines precise procedures for measuring vibration at the operator’s grip point and calculating permissible daily exposure times. This ensures compliance with defined exposure limits and allows accurate risk assessment.

Rather than isolating individual components, the entire cleaning system was analyzed — including pump, motor, valves, hoses, spray gun, lance, and nozzle. Only this holistic view reveals the complex interactions that influence vibration behavior and allows targeted countermeasures to be developed.

Medium-pressure systems up to 40 l/min, combined with ergonomic spray guns, do not exceed the 8-hour exposure limit specified in ISO 5349-1 — even under unfavorable operating conditions.

When correctly configured and maintained, medium-pressure cleaning systems in food processing environments present no significant hand-arm vibration (HAV) risk. Nevertheless, on-site measurement is recommended — especially for custom setups. Ergonomic equipment design and system-wide analysis remain key to long-term occupational health protection.

1. When do vibrations become a health concern?

According to ISO 5349-1, HAV exposure must remain below defined thresholds. In properly configured medium-pressure systems with ergonomic spray guns, these limits are not exceeded — meaning no health risk under normal operation.

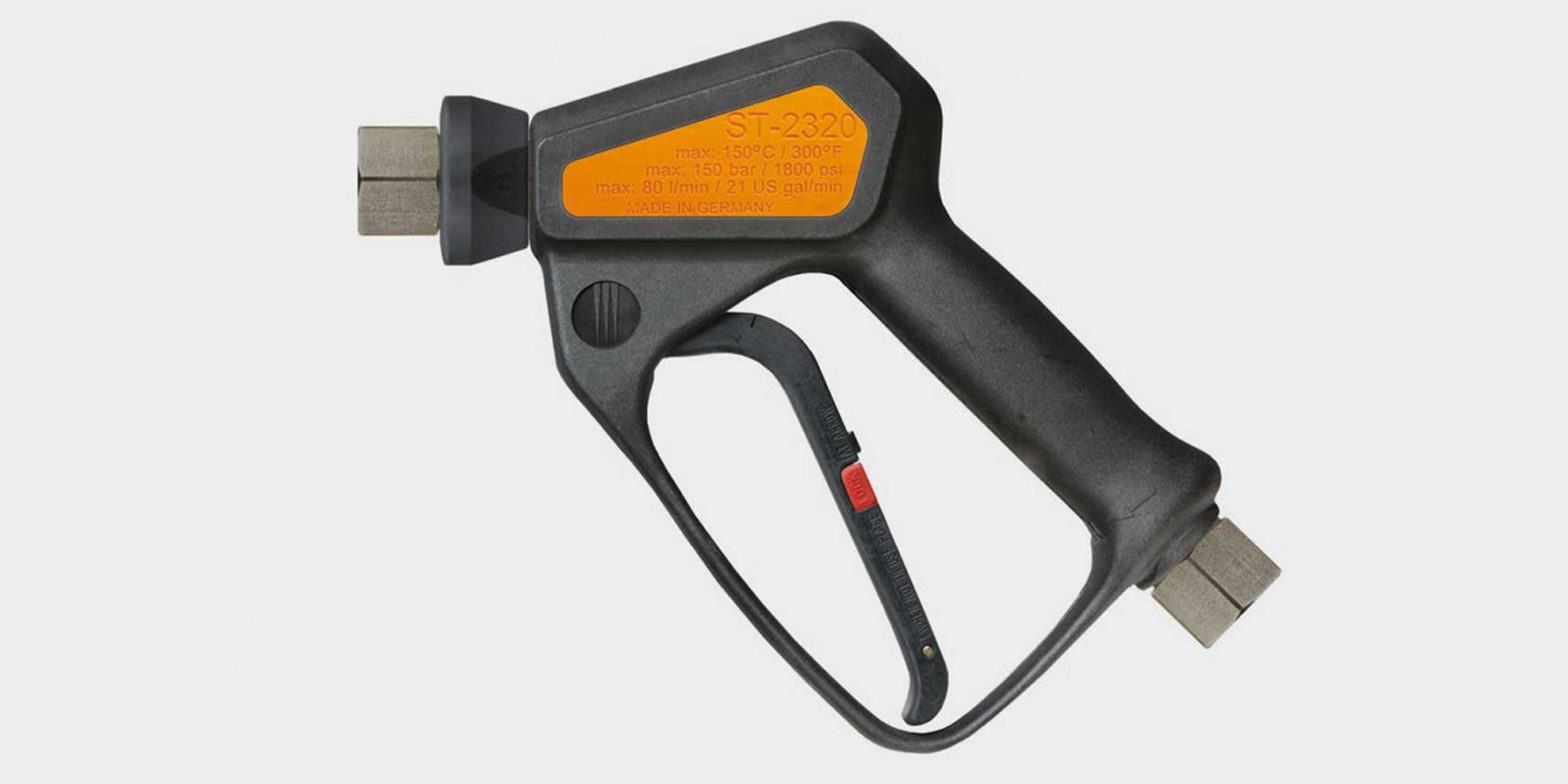

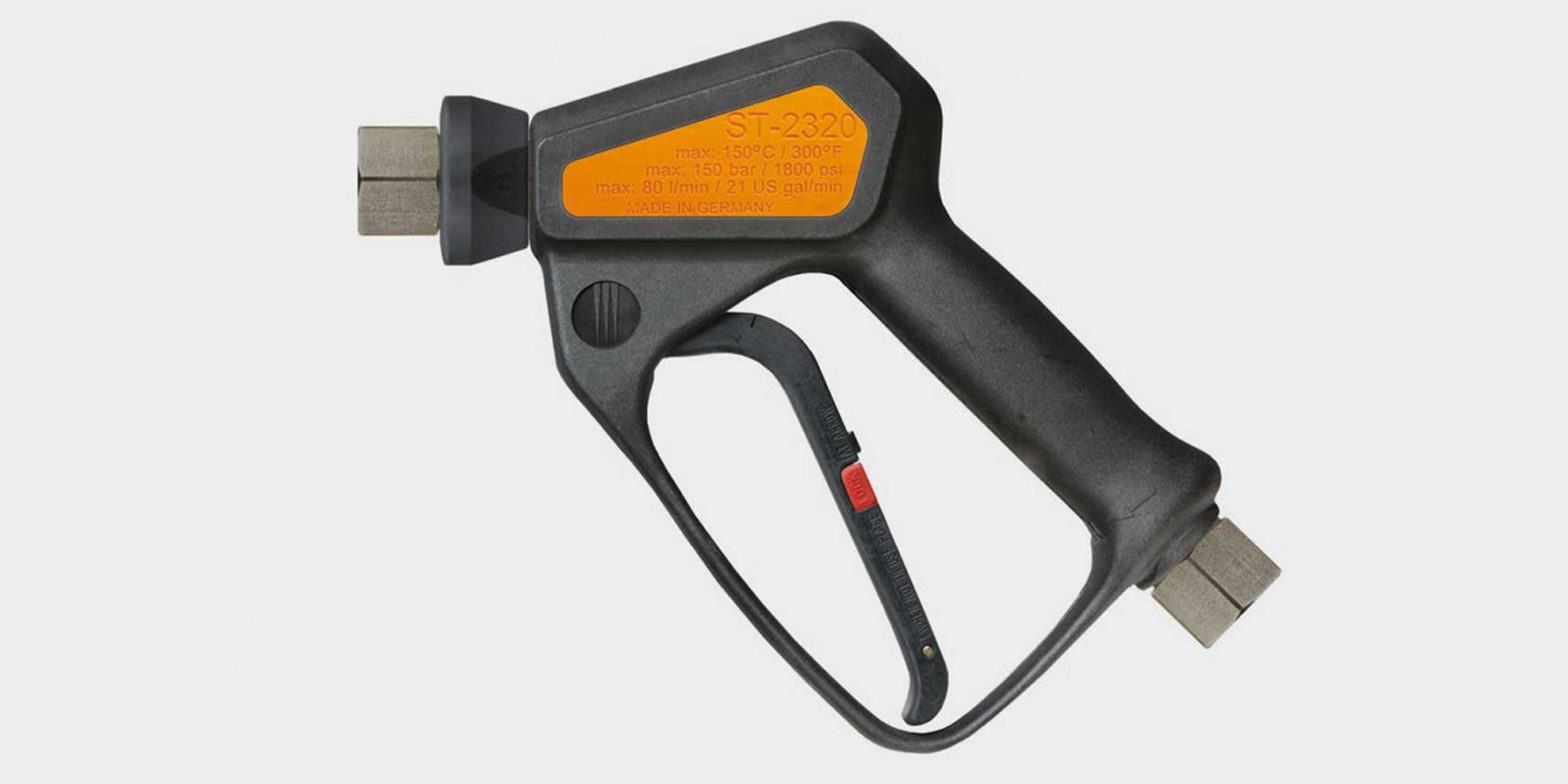

2. Do ergonomic spray guns really make a difference?

Yes. A well-designed model such as the ST-2725 improves grip comfort and posture, significantly reducing transmitted vibration compared to rigid mechanical adjustments.

3. Are all nozzles the same?

No. Rotating and oscillating nozzles generate far higher vibration levels than fixed nozzles. For prolonged cleaning sessions, fixed models are the preferred choice.

4. Should vibration levels be measured?

Measurement at the complete system level is recommended — particularly when using piston pumps, long hoses, or special nozzle configurations.

5. What can be done if vibration levels are too high?

The primary sources are typically the piston pump or rotating nozzle. Solutions include switching to vane pumps, using fixed nozzles, shortening hoses, or improving spray-gun ergonomics.

6. Are there legal requirements?

Yes. The EU Vibration Directive (2002/44/EC) mandates monitoring and limiting of HAV exposure. ISO 5349 serves as the technical reference standard for compliance.

| Component | Vibration Potential | Key Influence | Reduction Option |

| Piston pump | High | Flow rate, number of cylinders | Use vane pump, shorten operating cycles |

| Rotating nozzle | Medium to high | Rotational motion | Use fixed nozzle or limit use time |

| Ergonomic spray gun | Low | Grip design, posture | Ergonomic handle, soft-grip surface, posture training |

| Hose system | Low to medium | Length, internal flow mixture | Use shorter hoses, avoid overly rigid types |